Automatic Wrapping System

Fully automatic wrapper. The Hobart NGW uses an advanced sensor system and camera technology to automatically size your package, weigh, and wrap with optimal film efficiency by variable film roll selection and cut length. The NGW automatically stretches film around all 4 sides, seals the tray, computes price and applies the label. Electric motors power weigher/scale intake conveyor and autocentering. The NGW is a tank-based pneumatic driven wrapping system.

Semi-Automatic and automatic wrappers are primarily used to wrap fresh meat, seafood, produce, etc. in retail grocery meat rooms. The wrapped product can then be transferred to store shelves for purchase. These equipment varieties offer the grocers flexibility in product type and quantity to best fit the requirements of each store. With the NGW automatic wrapping machine, an operator loads the product on the tray and into the machine. The wrapper weighs, wraps, computes the price, and labels the product automatically. The product is then moved off the sealer belt and the next tray of product cycles through. The NGW can wrap up to 30 packages per minute and handle varying package sizes and weights. Models:

|

NGW1-LS2RL (Right to left, 1 Roll Film)

NGW1-LS2LR (Left to right, 1 Roll Film)

NGW2-LS2RL (Right to left, 2 Rolls Film)

NGW2-LS2LR (Left to right, 2 Roll Film)

|

Key Features & Benefits:A smaller footprint to make the most of your meat room space

Reduce downtime and maintenance costs with “copy machine” diagnostics; Alert icons (urgent messaging center) built-in to the user interface provide users with quick troubleshooting, and fewer service calls

Advanced closed-loop sensor system makes rapid, automated adjustments to optimize wrapping process and minimize downtime

Enhanced durable pneumatic system sealed to withstand meat room moisture and humidity

Hose down cleaning capability suitable for meat room environments 4-way film stretch and advanced camera technology optimizing film usage and reducing waste

Common Applications:Segment Specific Opportunities:- Meat rooms and food preparation areas in retail grocery stores, wholesale clubs, gourmet supermarkets, commissaries, etc.

Semi-Automatic Wrapping SystemThe Hobart CLAS-B semi-automatic wrapping system weighs your product and provides label application after a package has been hand wrapped. Semi-Automatic and automatic wrappers are primarily used to wrap fresh meat and seafood in retail grocers. The wrapped product can then be transferred to store shelves for purchase. These equipment varieties offer the grocers flexibility in product type and quantity to best fit the requirements of each store. Hobart offers a variety of accessories to go with the CLAS-B to customize the best solution for your meat room. Left to Right or Right to Left orientation must be determined for purchase. Models: |

CLAS-1RLB (Right to left) CLAS-1LRB (Left to right)

|

Common Applications:Manually wrap and automatically weigh and label trays of meat, seafood, cheese, produce, prepared foods, etc.

Segment Specific Opportunities:- Meat rooms and food preparation areas in retail grocery stores, wholesale clubs, gourmet supermarkets, commissaries, etc.

The Hobart hand wrapping system is designed for the operator to manually weigh and wrap a package and then place the wrapped package on the heated sealing pad. A separate, remote printer/console (HTsP, HTiP, HTxP, EPCP-5i/EPP-3) will compute the price and print the label for the operator to manually apply to the package. Available in ACCESS or HT versions, standard (-C) or Energy Smart (-ES). The Energy Smart version utilizes less energy by activating the heat sealing plate only when product is present. Models:

|

HWS-4-C (Standard)

HWS-4-ES (Energy Smart)

|

Common Applications:- Manually weigh, wrap and label trays of meat, seafood, cheese, produce, prepared foods, etc.

Segment Specific Opportunities:- Meat rooms and food preparation areas in retail grocery stores, wholesale clubs, gourmet supermarkets, commissaries, etc.

Compact Hand Wrap StationW32ES-1 Energy Smart wrap station is used with the CLAS-B semi-automatic wrapping system and can also be used as a stand alone wrap station. The Energy Smart wrap station utilizes less energy by activating the heat sealing plate only when product is present. W32C-5 Stand-Alone wrap station offers a sealing plate and 2-roll film capacity. Models:  |

W32C-5 (Stand Alone) W32ES-1 (Energy Smart Stand Alone)

|

Common Applications:- Manually wrap trays of meat, seafood, cheese, produce, prepared foods, etc.

Segment Specific Opportunities:- Meat rooms and food preparation areas in retail grocery stores, wholesale clubs, gourmet supermarkets, commissaries, etc.

A simple and convenient tabletop wrapper. This light-weight wrapper can easily be moved to where is it needed, when it is needed. Available in standard (A) or Energy Smart (ES-1) versions. Energy smart version utilize less energy by activating the heat sealing plate only when product is present. 6" x 15" hot plate for sealing, stainless steel wrapper surface, portable. Models:

|

625A

625ES-1 (Energy Smart)

|

Common Applications:- Manually wrap trays of meat, seafood, cheese, produce, prepared foods, etc.

Segment Specific Opportunities:- Table mounted in food preparation areas in retail grocery stores, wholesale clubs, gourmet supermarkets, commissaries, etc.

Product Offering & ModelsAutomatic

| Semi-Automatic

| Manual

| Accessories

| Printer

| Access Control Panels

| NGW1-LS2RL NGW1-LS2LR NGW2-LS2RL NGW2-LS2LR

| CLAS-1RLB CLAS-1LRB

| Hand Wrap W32C-5 W32ES-1 HWS-4-C HWS-4-ES

Tabletop 625A 625ES-1

| HRT5-3 (Roller/Discharge Table)

HRT-LD136 (Label Dispenser)

HRT-LD236 (Label Dispenser)

RBG-2 (Rotary Bin)

GRVCON-1 (Gravity Conveyor)

HWS-WRAPAD

ES-SHELF-RT ES-SHELF-LT

| EPP-3

| EPCP-5s

|

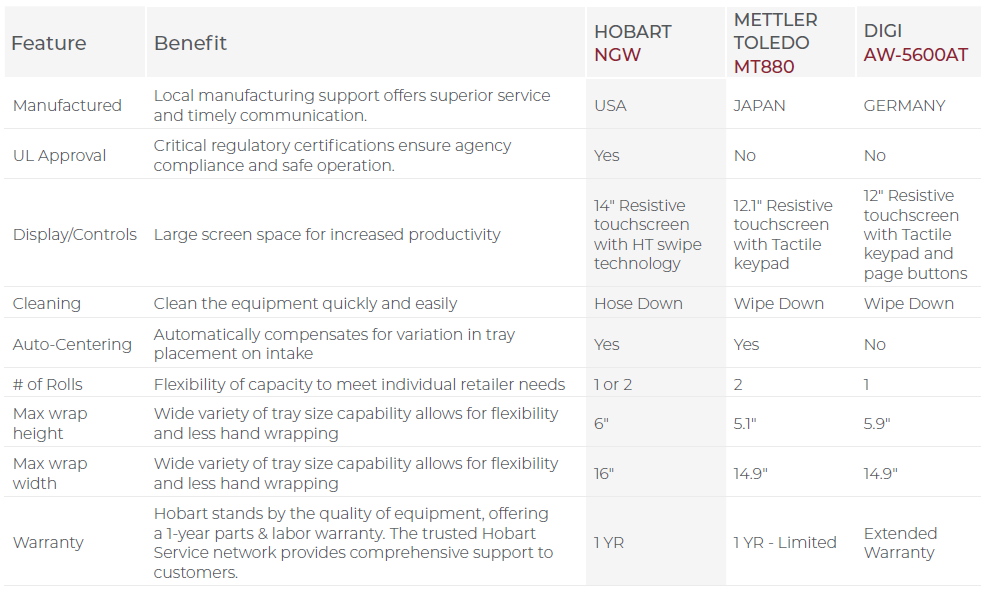

Competitive LandscapeHobart

NGW

| Mettler-Toledo

MT880

| Digi

AW4600/AW5600

| Headquarters

| |

| Glenview, IL

| Columbus, OH

| Tokyo, Japan

| Strengths

| | | • Long history of retail

weighing experience • Superior quality • Brand recognition • Trusted service network

| • Strong global presence • Portfolio includes scale at

point of sale

| • Extended warranty as standard • Small independent retailers

due to price • Multiple label appliers

| Weaknesses

|

|

| • Slower to bring new

technology to market | • Lack of innovation for scales • Slow response from

service network | • Lacking full retail portfolio

(other food equipment)• Long lead time on parts

• Poor service network typically spread out and can’t service same day |

|